Photos: Bundesarchiv

At the beginning of the 20th century, great architects such as Le Corbusier and Gropius were already working on how to create affordable living space that would meet the demands of the times. But while the system of prefabricated housing failed due to the dimensions and uniformity of the housing complexes, modern modular construction today offers enough examples of how to create attractive living space quickly, cheaply and with high quality thanks to industrial production.

Serial construction vs. prefabricated construction

New projects with industrially manufactured residential modules, which can be produced and erected in large numbers in the factory, show how fast, cost-effective and sustainable high-quality construction works. But although demanding architecture and serial building are no longer necessarily mutually exclusive, there are still reservations about this construction method in Germany. Its image is marked by monotonous, dreary prefabricated housing estates that emerged in the 1970s both in the former GDR and in the early Federal Republic, especially on the fringes of growing cities. This corresponded to the social demands of the time, in which architectural and social qualities were of secondary importance.

"What we as planners have always dreamed of is the industrialization and diversity of housing construction. Both are now finally possible thanks to the digitalisation of the entire planning and production process".

Joachim Brech, Dr. rer. pol, Dipl.-Ing. (Architektur, TUM)

New requirements for housing construction

However, society and building itself have changed and the requirements for the construction and renovation of residential buildings have become more complex - with the consequence that building has become more expensive and complex. This has to be counteracted with the possibilities of modern modular construction. The serial housing construction of today will not be the "slab of tomorrow". Instead, great importance is attached to a high architectural and urban planning quality, taking into account building culture concerns. It should be possible to adapt the residential buildings as flexibly as possible to the different location conditions and, in addition, they should be inexpensive, of the highest quality and quick to realise. Digitalisation also offers the opportunity to cope with the complexity of housing construction. So what is the difference in social, economic and architectural aspects between modular construction today and prefabricated construction in the past?

Visualization: Max Bögl Group

From the first cut of the spade to the rental in just a few weeks: With the framework agreement for serial and modular residential construction concepts, including the maxmodul system, housing companies are given the opportunity to realise new construction projects faster, easier, more cost-effectively and in high quality according to catalogue.

Differentiated building by means of planning catalog

At the time of the prefabricated housing estates, differentiation was not required and was only possible to a limited extent. According to a narrow housing catalogue and uniform guidelines, apartments of the same size and cut were generally built. The rules for the planning were determined by the optimized dimensions of the slab. Modular construction was also based on a set of rules. In contrast to prefabricated construction, however, with maxmodul it means "planning according to catalogue". On the basis of the regulations, type buildings and type ground plans for all relevant building types are summarised in a comprehensive planning compendium, which is continually being expanded. With this catalogue, different buildings can be configured depending on the situation and requirements (e.g. apartment mix).

Economic efficiency in all process phases

In the case of prefabricated buildings, serial, semi-industrial planning and construction was seen as a way of reducing costs and creating living space quickly and to a high standard of quality. Although there is also a limit for effectiveness and cost reduction in the industrial production of room modules, there is no such thing as a limit for the use of industrial technology. Digitalization, however, offers far-reaching opportunities to exceed these limits - if the individual parts of the value chain can be linked and interfaces reduced: from costing to execution and production planning to material procurement, transport logistics and assembly, including quality control. This is where economic and ecological aspects come together, as materials are used efficiently and construction site routes are saved. Above all, rule-based modular planning allows variants to be developed quickly, their data to be determined and visualized, which considerably shortens decision-making processes and makes them more transparent.

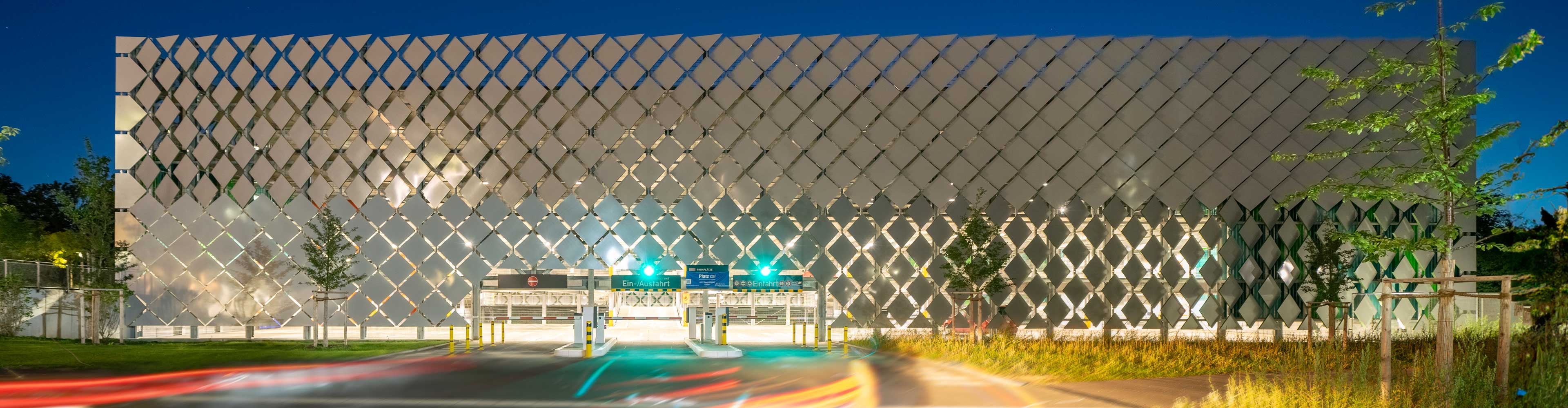

Photo: Reinhard Mederer

Architectural design diversity

No question: Even with industrially manufactured residential modules, architecturally inferior buildings can be erected today. As with prefabricated buildings, modular construction depends on what you do with the technology. With maxmodul, planning according to a catalogue not only allows a variety of urban planning configurations, but also a wide variety of architectural design options, for example with window and balcony elements. This means that the modular construction method can easily hold its own against conventional construction methods and - based on the same costs - even offers more options via the planning catalogue. Criticisms of the architecture of modular construction, as expressed by some quarters, have long been refuted by numerous practical examples.

Visualization: Max Bögl Group

One module for many segments

In principle, the majority of buildings can be typified, even if each building looks like a unique specimen. Because not only apartments, but also hotels, student residences, offices or kindergartens are based on the addition of the same rooms. This is where there is great potential for serial construction and thus for maxmodul. And even living is not the same as living, considering apartments for the elderly and handicapped, residential groups for students, shared accommodation, etc. These segments need to be structured like a catalogue, as is already the case with multi-storey housing.

Current projects