As the member of the Management Board responsible for Infrastructure 2, he is responsible for the Civil Engineering Germany division with the divisions Bridge Construction, Building Rehabilitation and Special Civil Engineering, Civil Engineering Netherlands and Tunnel Construction. After studying civil engineering at the Technical University of Munich, Martin Holfelder worked for over 30 years for a leading company in the German construction industry, both nationally and internationally, in a leading position in the infrastructure sector. With his move to Max Bögl, his strategic focus is particularly on the integrated further development of the group of companies - and this in close cooperation with the other divisions. In addition to the profitable expansion of the above-mentioned business segments, the development of new business fields and technologies in the course of the energy turnaround should also be mentioned here as an example. For him, Lean Management and BIM are key issues for the future, which must continue to be successfully implemented in order to remain competitive. Martin Holfelder stands for know-how and experience in special foundation engineering, tunnelling and civil engineering, in the responsible management of a business unit and in the acquisition and execution of complex infrastructure projects. His motto is: "Do and create with head, heart and hand - team-, goal- and decision-oriented, strategic, innovative, value-based and customer-oriented". If there is still time for private things besides work, Martin Holfelder, who has his roots in the Upper Palatinate, loves to relax with his family in sports, art and music. In addition, he enjoys travelling and getting to know the world and other cultures.

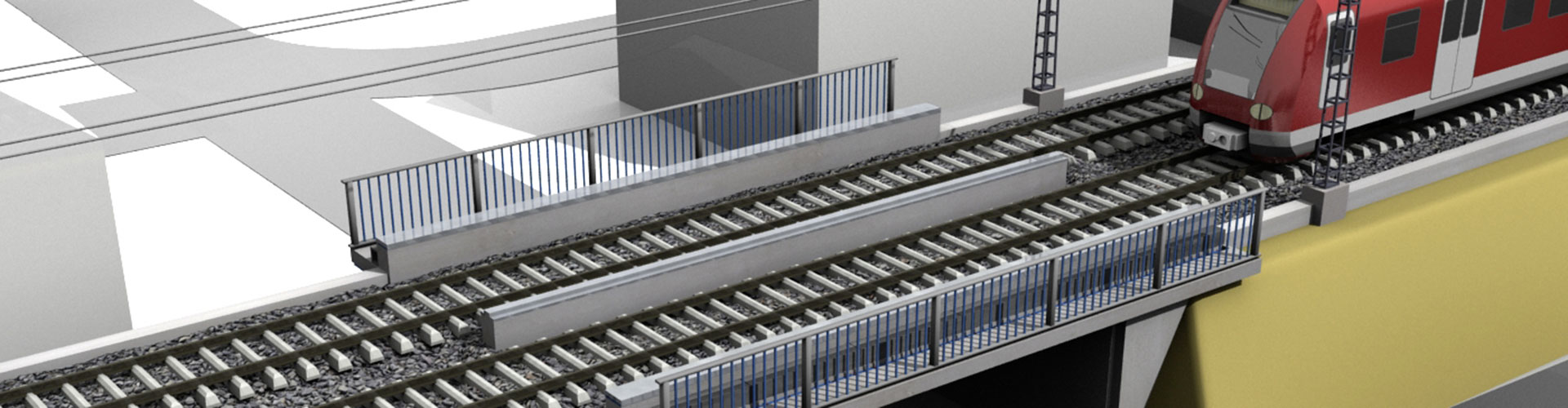

Hybride spoorbruggen Bögl

New Board Member Infrastructure 2

21.02.2018

A portrait of Martin Holfelder. Since 1 January 2018 Martin Holfelder has been a new member of the Executive Board of the Max Bögl Group.