Germany's most modern high-speed line was officially opened on 8 December 2017 with two special trains travelling and a major ceremony in Berlin in the presence of Federal Chancellor Angela Merkel, Federal Minister Christian Schmidt and several heads of state governments. Exactly 623 kilometres (via Halle) and 652 kilometres (via Leipzig) lie between the main stations of the German capital and the Bavarian metropolis. The ICE Sprinter, which stops three times a day on its way only in Halle, Erfurt and Nuremberg, shortens the travel time by a third from six hours to 3:55 hours. By way of comparison, the regular ICE can cover the distance in 4:30 hours.

Closing the gap in the European high-speed rail network

With a top speed of up to 300 km/h, the ICEs are on the move on sections of the newly built sections. At the heart of the new section that has now gone into operation, a nearly 110 kilometer long section through Thuringia, 22 tunnels and 27 viaducts were built. In addition to the national advantages, this high-speed line also brings Europe's North and South a little closer: it is an important component of the Trans-European Transport Networks (TEN-T) and, thanks to a common train control system, will make it possible in future to travel across national borders without changing railcars and without intermediate stops.

Milestones for Max Bögl

Together with the new Nuremberg-Ingolstadt-Munich line, the transport project German Unity No. 8 (VDE 8) with the new construction and extension of the lines between Nuremberg, Erfurt, Halle, Leipzig and Berlin is a project of superlatives. In 1991, after the reunification of Germany, the Federal Government decided that the new turbo line should sustainably improve the rail connections for passenger and freight traffic. The Max Bögl Group also played a major role in the implementation of this infrastructure measure, providing difficult engineering, tunneling and civil engineering services for the following sections:

NBS Nürnberg-Ingolstadt, Los Nord (35 km) between Feucht and Greding:

- Turnkey construction of the line section up to OK Rail incl.

- Göggelsbuch tunnel (2,287 m) and open construction (1,330 m)

- Construction of various earthworks and bridges

- Ballastless track system Bögl

NBS Ebensfeld–Erfurt (107 km):

- Tunnels: Finnetunnel (6,886 m), Silberberg (7,391 m), Brandkopf (1,494 m) and Lohmeberg (688 m)

- Railway bridges over the Wohlrose valley and Schobsetal

NBS Ebensfeld-Erfurt, Erfurt-Ilmenau section (32.5 km):

- Permanent way in slab track Bögl

- Noise barriers system Bögl

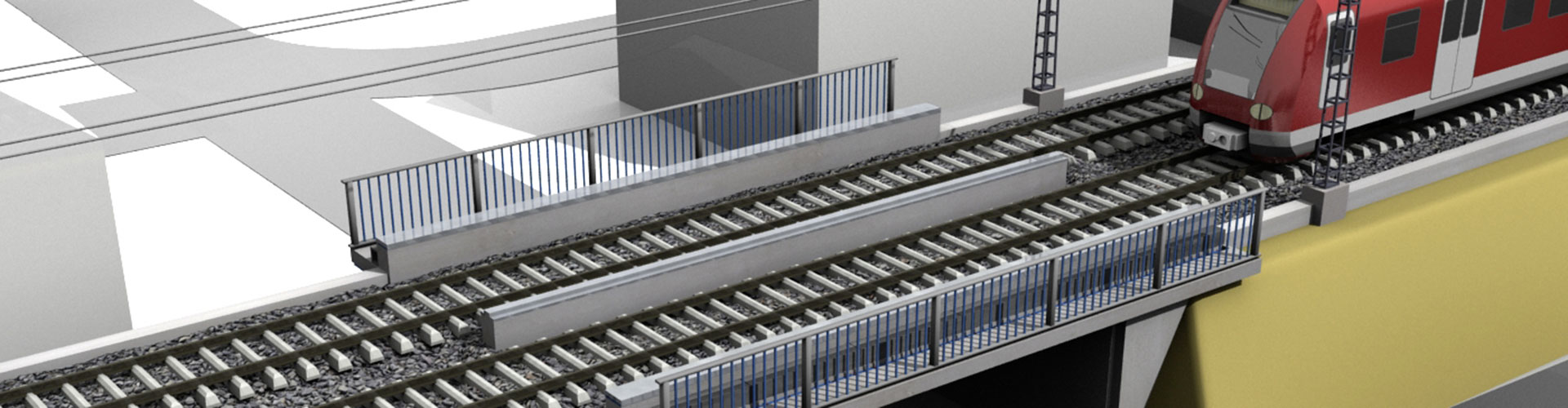

NBS Nuremberg-Ebensfeld (infrastructure measures Bubenreuth)

- Earthworks, substructure: 352,220 m³

- Drainage: 8,124 m

- Diffusers: 305 m

- shafts: 261 pieces up to max. 8 m depth

- Provisional platforms: 1,200 m²

- Overpasses: 13,000 m³ concrete, 10,000 m drilled piles, 7,000 m² sheet piles