Premiere for the new Max Bögl System Construction Bavaria business unit - first order in Mühldorf am Inn

Great joy for the hall construction managers of the construction company Max Bögl - last Wednesday the contract for the construction of a multi-user center in Mühldorf am Inn was officially signed. The hall, which can be divided into up to four rental sections, is located in the immediate vicinity of the A94 motorway and on the state roads 2092, 2352 and 2550 as well as the B 299 and is thus located at a favourable traffic intersection to Munich and Passau.

Contract signing in Traunstein at GreenRock (from left to right): Mr. Jens Edelmann - Project Manager, GreenRock | Mr. Franz Hauk - Managing Director, GreenRock | Mr. Klaus Lenkeit - Head of System Construction Bavaria Division, Max Bögl | Mr. Matthias John - Head of Commercial Project Management Munich, Max Bögl

Contract signing in Traunstein at GreenRock (from left to right): Mr. Jens Edelmann - Project Manager, GreenRock | Mr. Franz Hauk - Managing Director, GreenRock | Mr. Klaus Lenkeit - Head of System Construction Bavaria Division, Max Bögl | Mr. Matthias John - Head of Commercial Project Management Munich, Max Bögl

Photo: GreenRock

Client of the project is the medium-sized real estate developer GreenRock Management GmbH & Co KG, whose core business is sustainable and innovative projects in the region of Upper Bavaria.

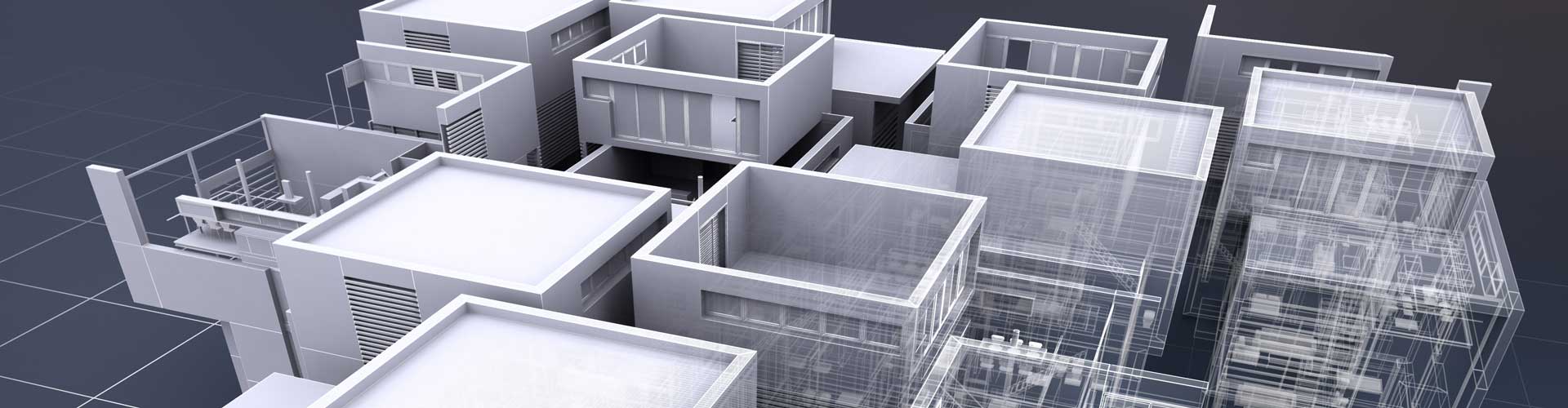

Visualization of the planned logistics hall "GR1" in Mühldorf am Inn

Visualization of the planned logistics hall "GR1" in Mühldorf am Inn

Visualization: GreenRock / newages.at

Mr Patrick Stelzer - Director GreenRock - about the cooperation with Max Bögl: "We chose Max Bögl because as a young company we rely on the decades of experience of the Max Bögl Group as general contractor. The willingness to innovate as well as the commitment in the acquisition phase made the decision for Max Bögl easy for us. We are looking forward to a successful joint project implementation."

Sustainability

The project is characterised in particular by its high standards of sustainability and flexibility. First and foremost, the hall will be built to the KfW55 standard and a DGNB certificate in gold will be sought. The sustainable energy concept includes, for example, a photovoltaic system on the hall roof, an energy-efficient façade or LED hall lighting. This results in low ancillary costs for the property and for the future tenants. In addition, the property will be equipped with a green façade and wide green strips as outdoor facilities.

Visualization of the planned logistics hall "GR1" in Mühldorf am Inn

Visualization of the planned logistics hall "GR1" in Mühldorf am Inn

Visualization: GreenRock / newages.at

Flexibility, on the other hand, is achieved due to the fact that the hall is designed for one to four tenants and can be individually adapted. Inside the hall, the mezzanine areas can be converted into office or storage space as required. The clear hall height of 10.00 m also offers space for versatile use. In addition, each of the four sections is equipped with a ground-level ramp and four docking stations.

Scope of services

For the project in Mühldorf am Inn Max Bögl based on an existing design planning and transferred the logistics hall into the Max Bögl hall system - i.e. designed the construction including support grid according to the general conditions on site. This construction is prefabricated in Max Bögl's own precast factory at headquarters in Sengenthal and delivered just-in-time to the construction site, regardless of weather conditions. Accordingly, Max Bögl's scope of services is divided into the construction work on the one hand, and the further planning and consulting of the medium-sized company on the other.

New business division

The multi-user center for GreenRock represents the first order for the "System Construction Bavaria" business area, which was newly bundled in September 2018, with its division manager Mr. Klaus Lenkeit. The project will be handled by Max Bögl branch in Munich. There the Max Bögl Group employs almost 100 employees from the most different occupational groups - from architects over buyers up to site managers. In the various, regionally localised system construction departments, Max Bögl brings together his competence in the construction of halls of any kind - whether logistics, storage or production - and offers customers advice and planning throughout all project phases in addition to the pure construction work.

Visualization of the planned logistics hall "GR1" in Mühldorf am Inn

Visualization of the planned logistics hall "GR1" in Mühldorf am Inn

Visualization: GreenRock / newages.at

Mr. Klaus Lenkeit sums up his first order as follows: "We are looking forward to the implementation of our first project, especially as it is a logistics hall with a promising future, which impresses with a sustainable concept, a good location and a flexible subdivision. Last but not least, we look forward to an equally promising and long-term cooperation with Green Rock."

The ground-breaking ceremony for the construction project is planned for April / May, depending on the date of the building permit. After a construction period of only around 9 months, the project is to be completed at the beginning of 2020.

Contact:

Patrik Fanderl

Marketing Building

Tel.: +49 9181 909-13906

E-Mail: pfanderl@max-boegl.de

Klaus Lenkeit

Head of System Construction Division Bavaria

Tel.: +49 9181 909-15626

E-Mail: klenkeit@max-boegl.de