There are more than 25,000 railway bridges in Germany. Around one third of these are in poor condition, and 1,100 bridges are so badly damaged that instead of being rehabilitated only demolition and new construction are acceptable. For the replacement of structures with short spans, Max Bögl now offers a modular system, the Hybrid Railway Bridge, which fully exploits the advantages of serial production in terms of construction time, quality and economy.

Modular System

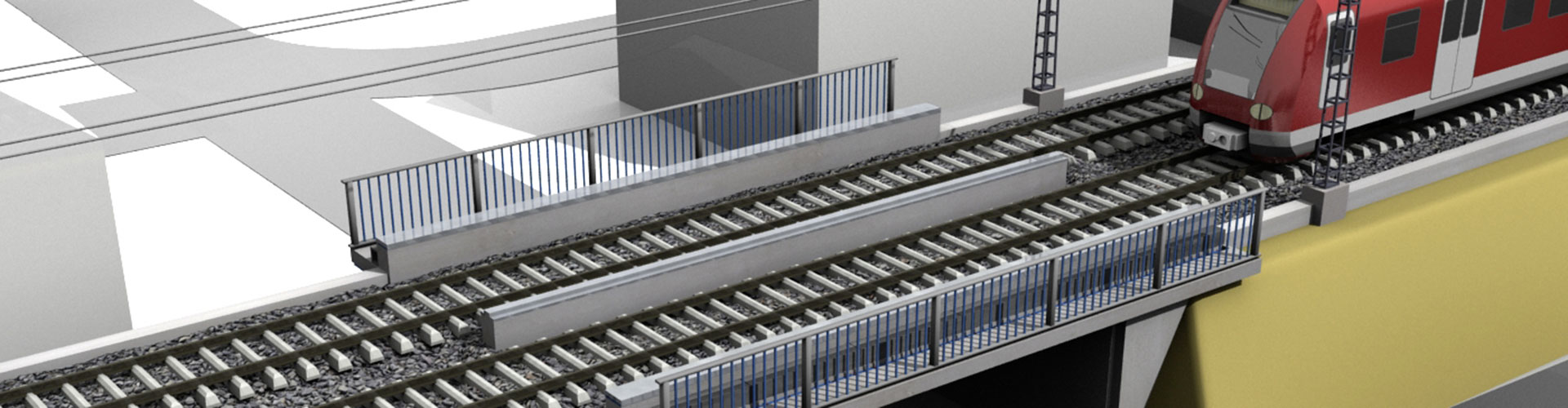

The Max Bögl Group with the Hybrid Railway Bridge Bögl can already be part of the solution during the property planning stage. Designed for single and double-track railway bridges with spans of up to 15 metres and low overall height, the hybrid construction of the railway bridge combines the classic advantages of steel and concrete. Thanks to industrial production in the factory, the individual system components can be continuously prefabricated, stored in a building yard and assembled on site to form various individual structures in the shortest possible construction time.

Advantages

- Segmented System: Transport by Road or Rail

- Industrial Prefabrication: High Quality and accuracy of components

- Standardized assemblies, production and construction: controlled production process, short construction time, delivery and assembly just in time

- Compliance with the standard track superstructure: simple maintenance and servicing

- BIM-based process: efficient utilization of the digital value chain during the entire building life cycle

- Production and assembly also by license partner